Pneumatic Conveying

Pneumatic conveying systems are an essential part of various industries, enabling the efficient transportation of bulk materials using air or gas. These systems are widely used in food processing, cement, pharmaceuticals, chemicals, and many other industries to move powdered, granular, and bulk solids efficiently and hygienically. In Jaipur, Subhawati Ventilation Systems is a renowned name in manufacturing high-quality pneumatic conveying systems, offering advanced solutions for industrial air handling and pollution control.

The systems is totally enclosed and if it is required the system can operate entirely without moving parts coming into contact with the conveyed material. High, low and negative pressure can be used to convey materials.

A wide variety of material are handled in powdered and granular form, and a large number of different industries have processes that involve their transfer and storage. Some of the industries in which bulk materials are conveyed include agriculture, mining, chemical, pharmaceutical and metal refining & processing.

What is Pneumatic Conveying?

Pneumatic conveying is a method of transporting bulk materials through a pipeline by means of air pressure or vacuum. Unlike mechanical systems, pneumatic conveying utilizes air or another gas to move materials such as powders, granules, and pellets. It is commonly used in industries such as food processing, pharmaceuticals, chemicals, and cement manufacturing where dust control and cleanliness are critical.

There are three types of pneumatic conveying systems, each with its unique set of applications:

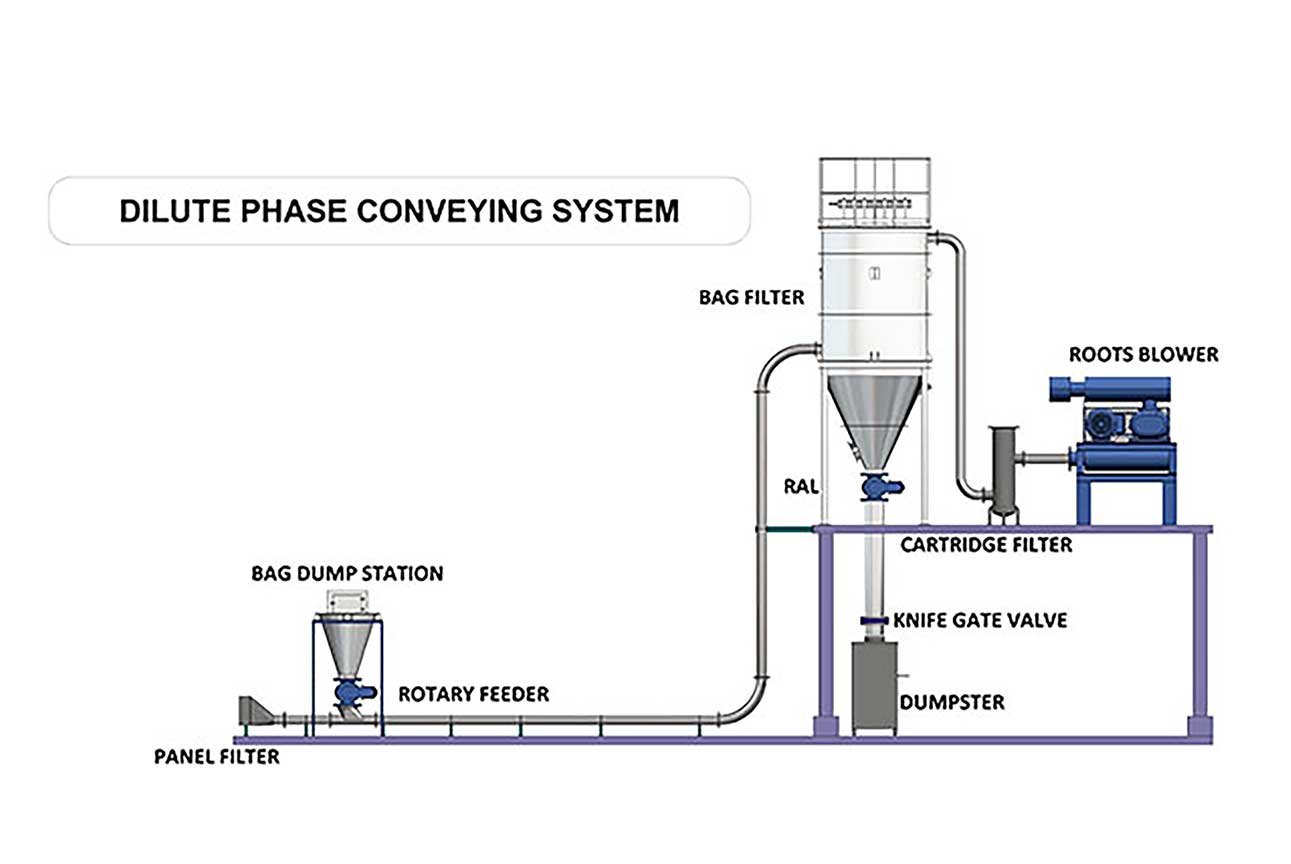

Dilute Phase Pneumatic Conveying: In this type, the material is transported in a suspended state using high-velocity air. The material is continuously fed into the conveying line and pushed to its destination. It is suitable for materials that are not sensitive to degradation, such as grains, sugar, and plastics.

Dense Phase Pneumatic Conveying: Dense phase systems operate at lower speeds, but higher pressure, moving material in batches rather than in a continuous flow. This method is more energy-efficient and is ideal for transporting fragile or abrasive materials that need protection from breakage, such as sand, cement, or powders.

Vacuum Conveying: A vacuum system uses suction to draw materials through the pipeline. It is particularly useful in applications where dust containment and minimal spillage are important, such as pharmaceutical production or fine powder handling.

Why Pneumatic Conveying in Jaipur?

Jaipur, being a major industrial hub in India, is home to a variety of industries that require advanced material handling solutions. Pneumatic conveying systems offer significant advantages over traditional mechanical conveyors, making them an ideal choice for Jaipur’s growing industrial sectors.

Space-Saving and Flexibility: In the crowded urban industrial areas of Jaipur, space is always a constraint. Pneumatic conveying in Bhiwadi are highly adaptable and can be installed in existing spaces without the need for large structural changes. The pipeline layout can be adjusted to navigate around obstacles, making them perfect for tight factory environments.

Dust-Free Operations: With Jaipur’s environmental regulations becoming stricter, industries are focusing on minimizing pollution and dust generation. Pneumatic conveying systems are sealed, which means they produce minimal dust and help keep the work environment clean. This is crucial for industries like food processing and pharmaceuticals, where hygiene is paramount.

Energy Efficiency: Modern pneumatic conveying systems are designed to be energy-efficient, reducing operational costs. This is particularly important for industries in Jaipur, where energy consumption is a significant concern due to high electricity costs and frequent power shortages.

Versatility: Pneumatic conveying is not limited to one type of material. It can handle a wide variety of materials, from fine powders to larger granules, making it suitable for a diverse range of industries in Jaipur, including cement, chemicals, pharmaceuticals, and food processing.

Applications of Pneumatic Conveying Systems

Bulk Material Handling: Pneumatic conveying systems are widely used for handling bulk materials such as cement, fly ash, flour, grains, and powders in industries that require continuous material movement.

Dust-Free Operations:These systems ensure dust-free material transfer, reducing air pollution and improving workplace hygiene, particularly in food processing and pharmaceutical industries.

Space-Saving Solution: Compared to traditional mechanical conveyors, pneumatic conveying systems require minimal space, making them ideal for industries with limited floor area.

Long-Distance Conveying: Pneumatic conveying allows material transport over long distances without significant loss, making it suitable for industries with large production areas.

Advantages of Choosing Subhawati Ventilation Systems

Reduced Material Degradation: For industries handling fragile or sensitive materials, such as food or chemicals, pneumatic conveying ensures that materials are transferred gently, reducing the risk of damage or degradation.

Customization and Engineering Expertise: Subhawati Ventilation Systems specializes in custom-designed pneumatic conveying systems to meet the unique needs of different industries. The company’s expert engineers work closely with clients to understand their requirements and design systems that optimize efficiency and cost-effectiveness.

Enhanced Safety: The enclosed nature of pneumatic conveying systems minimizes dust generation, reducing the risk of explosions in industries dealing with flammable powders or chemicals.

High-Quality Materials and Advanced Technology: All pneumatic conveying solutions by Subhawati Ventilation Systems are manufactured using high-quality materials and the latest technology, ensuring durability, reliability, and long service life. The company incorporates advanced automation and control systems to improve performance and reduce manual intervention.

Environmental Benefits: In a city like Jaipur, where air quality is a major concern, pneumatic conveying systems help reduce the environmental impact of industrial processes by minimizing dust and emissions.